Signs Your Epoxy Floor Installation Went Wrong and How We Can Help

- SCDS

- Feb 6

- 3 min read

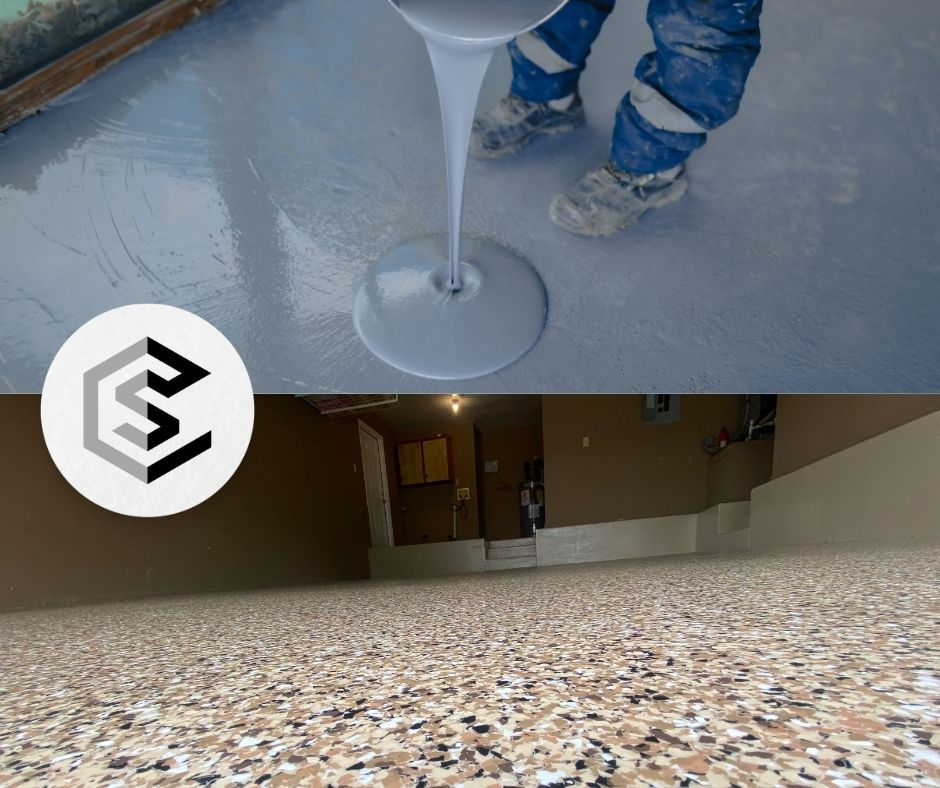

Installing an epoxy floor in your garage or workspace can transform the area into a durable, attractive surface. But what if the results don’t meet your expectations? Sometimes, despite your best efforts, an epoxy floor installation can go wrong. Recognizing the signs early can save you time, money, and frustration. This post will help you identify common problems with epoxy floors and explain how professional help can fix these issues.

Common Signs Your Epoxy Floor Installation Is Not Right

When an epoxy floor is installed correctly, it should look smooth, glossy, and even. If you notice any of the following problems, your installation may have issues:

Peeling or Flaking Surface

One of the most obvious signs is peeling or flaking. This happens when the epoxy does not bond properly to the concrete. Causes include:

Poor surface preparation, such as not cleaning or etching the concrete

Applying epoxy over moisture or oil stains

Using the wrong type of epoxy for the surface

Peeling not only looks bad but also exposes the concrete underneath, reducing protection.

Bubbling or Blistering

Bubbles or blisters on the surface indicate trapped air or moisture. This can occur if:

The concrete was damp during application

The epoxy was mixed improperly, introducing air

The temperature or humidity was too high during curing

Bubbles weaken the floor and can lead to further damage.

Uneven or Patchy Appearance

If your floor looks blotchy, dull in some areas, or has visible brush or roller marks, the epoxy may not have been applied evenly. This can happen when:

The epoxy is applied too thick or too thin in spots

The coating was not spread quickly enough before it started to set

Multiple coats were not applied correctly

Uneven floors can be slippery or rough, affecting safety and comfort.

Cracking or Chipping

Cracks or chips in the epoxy surface suggest that the floor is not flexible enough or the concrete underneath is moving. This can result from:

Applying epoxy on a floor with existing cracks without repair

Using a low-quality epoxy that lacks durability

Heavy impacts or loads soon after installation

Cracks allow dirt and moisture to penetrate, causing further deterioration.

Yellowing or Discoloration

Epoxy floors should maintain their color and shine for years. Yellowing or discoloration often means:

Exposure to UV light without proper UV-resistant coating

Using epoxy not designed for your environment

Chemical spills or harsh cleaning agents damaging the surface

Discoloration affects the floor’s appearance and may signal weakening.

What You Can Do If Your Epoxy Floor Looks Wrong

If you spot any of these signs, don’t panic. Some problems can be fixed with proper care or reapplication, but others require professional attention. Here are steps you can take:

Assess the damage carefully. Take note of all visible issues and how widespread they are.

Avoid heavy use. Limit traffic on the floor to prevent worsening damage.

Clean gently. Use mild cleaners and avoid harsh chemicals that could worsen problems.

Contact experts. A professional can inspect the floor, identify the root cause, and recommend the best solution.

How Professional Help Can Restore Your Epoxy Floor

Fixing a faulty epoxy floor requires experience and the right tools. Professionals can:

Prepare the surface properly. They will remove old epoxy, clean, and repair the concrete to ensure a strong bond.

Choose the right materials. Experts select epoxy formulas suited for your space and conditions.

Apply coatings evenly. Skilled technicians use proper techniques to avoid bubbles, streaks, or uneven layers.

Add protective finishes. UV-resistant and anti-slip coatings improve durability and safety.

Provide warranties. Professional services often come with guarantees for peace of mind.

Getting help early can prevent costly replacements and extend the life of your floor.

When to Call Us for Epoxy Floor Assistance

If your epoxy floor shows peeling, bubbling, cracking, discoloration, or unevenness, give us a call. We specialize in diagnosing and fixing epoxy floor problems in garages and other spaces. Our team will:

Inspect your floor thoroughly

Explain the causes of the issues

Offer clear options for repair or replacement

Deliver high-quality results that last

Don’t let a poor epoxy floor installation ruin your space. Reach out today to get your floor back to its best condition.

Comments